Evaluation Guide

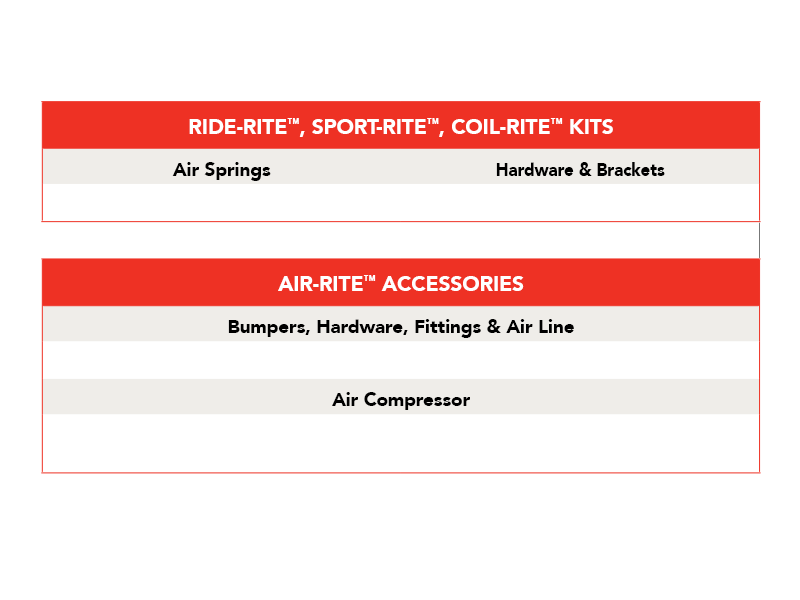

Firestone Airide (Ride-Rite) air springs are designed to provide years and thousands of miles of trouble-free service. Their durability is such that they will often outlast other maintenance items on your suspension, such as bushings, shocks and other components. Firestone Airide Automotive Aftermarket air springs are warranted to be free of material defects and/or workmanship for as long as the original purchaser owns the vehicle on which it was originally installed. The hardware and brackets that accompany the air spring are warranted for a period of 24 months. This limited warranty begins on the original retail delivery date. Firestone may provide replacement parts if the hardware and/or brackets were determined by Firestone to be warrantable. All labor and incidental costs associated with replacing the defective air spring are the responsibility of the consumer.

Firestone offers a complete line of air springs with products available for a variety of applications. Since each individual air spring is closely examined and pressure tested at the factory, the vast majority of warranty claims are found not to be defective, and failure typically occurs because of abuse caused by other problems associated with the suspension or a lack of sufficient air pressure.